Cosmetic manufacture is a complex blend of science, engineering, and creativity. From selecting raw materials to producing creams, powders, and liquids, every step requires precision.

The modern cosmetics industry combines technology with strict standards. Factories use controlled environments, testing protocols, and systematic processes to ensure products meet both safety and performance requirements.

The Scope and Importance of the Cosmetics Industry

The global cosmetics industry produces thousands of products daily, ranging from skincare creams to makeup items. Cosmetic manufacture drives jobs, research, and innovation in chemistry, biology, and materials science.

Regulatory bodies monitor safety and labeling, making the industry highly structured. Advances in formulation, ingredient science, and manufacturing technologies have expanded what is possible in cosmetic production.

From Concept to Consumer: An Overview of the Production Process

Cosmetic manufacture starts with research and formulation. Scientists test ingredient combinations for stability, texture, and safety. Once a formula is finalized, it moves to pilot production for small-scale testing.

After quality control and regulatory checks, products are scaled up, packaged, and distributed. Each step, from mixing raw materials to final packaging, ensures that the finished cosmetic meets consumer expectations and industry standards.

Understanding Cosmetic Ingredients

Cosmetic manufacture relies on a precise balance of ingredients to ensure products are safe, stable, and effective. Each component plays a role, whether in performance, texture, or appearance, making ingredient selection critical.

Active Ingredients vs. Inactive Ingredients

Active ingredients in cosmetic manufacture are the compounds that produce measurable effects, such as hydration, exfoliation, or sun protection. Their concentration and stability are carefully controlled during production.

Inactive ingredients, also called excipients, help deliver active ingredients, improve texture, and extend shelf life. Both types must be compatible to avoid separation or instability in the final product.

Natural vs. Synthetic Components

Natural ingredients, like plant extracts or minerals, are widely used in cosmetics for their functional or aesthetic properties. Synthetic components are engineered for consistency, stability, and targeted performance.

Cosmetic manufacture often blends natural and synthetic compounds to achieve desired effects. Rigorous testing ensures that both sources meet safety and efficacy standards before inclusion in formulas.

The Role of Preservatives, Fragrances, and Colorants

Preservatives prevent microbial growth in cosmetic products, ensuring safety during shelf life. Fragrances enhance user experience but must be carefully tested for irritation potential.

Colorants provide visual appeal, from vibrant eyeshadows to lip products. Each additive is evaluated for stability and compatibility with other ingredients, playing a crucial role in reliable cosmetic manufacture.

Formulation and Product Development

Cosmetic manufacture begins with careful formulation, where chemists combine ingredients to meet specific goals like texture, color, and performance. Product development involves multiple iterations and precise measurements.

Research and Development in Cosmetics

Research and development (R&D) is the foundation of cosmetic manufacture. Scientists test new ingredients, evaluate formulations, and refine textures to create effective and safe products.

R&D also considers consumer preferences, regulatory requirements, and market trends. Prototype batches are produced and analyzed for consistency, ensuring the final product performs as intended.

Testing for Safety and Stability

Before mass production, every formula undergoes safety and stability testing. This includes checking for microbial contamination, chemical stability, and reactions under different temperatures.

Stability tests ensure creams, powders, and liquids maintain their texture, color, and performance over time. Safety testing also evaluates potential irritation or allergenic reactions, meeting regulatory standards.

Creating Different Product Forms: Creams, Powders, and Liquids

Different product forms require specialized cosmetic manufacture techniques. Creams often need emulsification to combine oil and water phases smoothly. Powders require milling and pressing for even texture.

Liquids, like serums or foundations, are blended with precise viscosity and flow characteristics. Each form demands careful control of ingredients, mixing, and processing to ensure quality and consistency in the final product.

Manufacturing Processes for Different Cosmetic Types

Cosmetic manufacture uses specialized processes tailored to each product type. From emulsifying creams to pressing powders, precise techniques ensure consistent texture, color, and stability.

Each step is monitored carefully, combining scientific principles with mechanical methods to transform raw ingredients into safe, appealing beauty products.

Emulsification and Mixing Techniques

Emulsification is essential in cosmetic manufacture for creams and lotions. Oil and water phases are combined using high-shear mixers to create stable emulsions.

Mixing must be controlled for speed, temperature, and duration to prevent separation. Additives like thickeners or stabilizers are included to maintain texture and extend shelf life.

>> Boost Your Cosmetics Brand’s Competitiveness in the Market

Milling and Pressing Powders

Powders, such as eyeshadows or face powders, undergo milling to achieve uniform particle size. Fine particles ensure smooth application and consistent pigmentation.

After milling, powders may be pressed into pans or compact forms. This process requires precision to maintain density, prevent crumbling, and achieve the desired finish.

Filling and Packaging Liquids and Creams

Liquid and cream cosmetics are filled using automated or semi-automated equipment to ensure accurate volume and hygiene. Packaging must prevent contamination and preserve product stability.

Containers are sealed and labeled under controlled conditions. Cosmetic manufacture at this stage balances functionality, safety, and presentation to meet both regulatory and consumer standards.

Quality Control and Assurance

Quality control is a central part of cosmetic manufacture, ensuring every batch meets standards for texture, color, safety, and performance. Rigorous checks prevent defects and maintain consumer trust.

Cosmetic manufacturers combine scientific testing, visual inspection, and regulatory compliance to verify that products are consistent and safe before reaching the market.

Ensuring Consistent Texture and Color

During cosmetic manufacture, each batch is evaluated for uniform texture and color. Instruments measure viscosity, spreadability, and pigment distribution to ensure consistency.

Any variation can affect performance or appearance. Repeated testing during and after production ensures the final product matches the intended formulation and visual standards.

Microbial Testing and Safety Standards

Cosmetics are tested for microbial contamination to prevent product spoilage and skin infections. Preservative systems are evaluated to maintain safety throughout shelf life.

Microbial testing includes bacterial, yeast, and mold checks. Compliance with safety standards ensures that creams, powders, and liquids remain safe for consumer use.

Regulatory Compliance in Manufacturing

Cosmetic manufacture must adhere to local and international regulations regarding ingredients, labeling, and safety. Regulatory compliance ensures products are legally marketable.

Documentation, batch records, and testing reports are maintained for audits. Following these standards protects consumers and guarantees consistent quality across all production runs.

Innovative Technologies in Cosmetic Production

Modern cosmetic manufacture increasingly relies on technology to improve efficiency, precision, and sustainability. Automation, nanotechnology, and eco-friendly methods are transforming how products are developed and produced.

These innovations help maintain consistent quality, reduce waste, and enable more advanced formulations for creams, powders, and liquids.

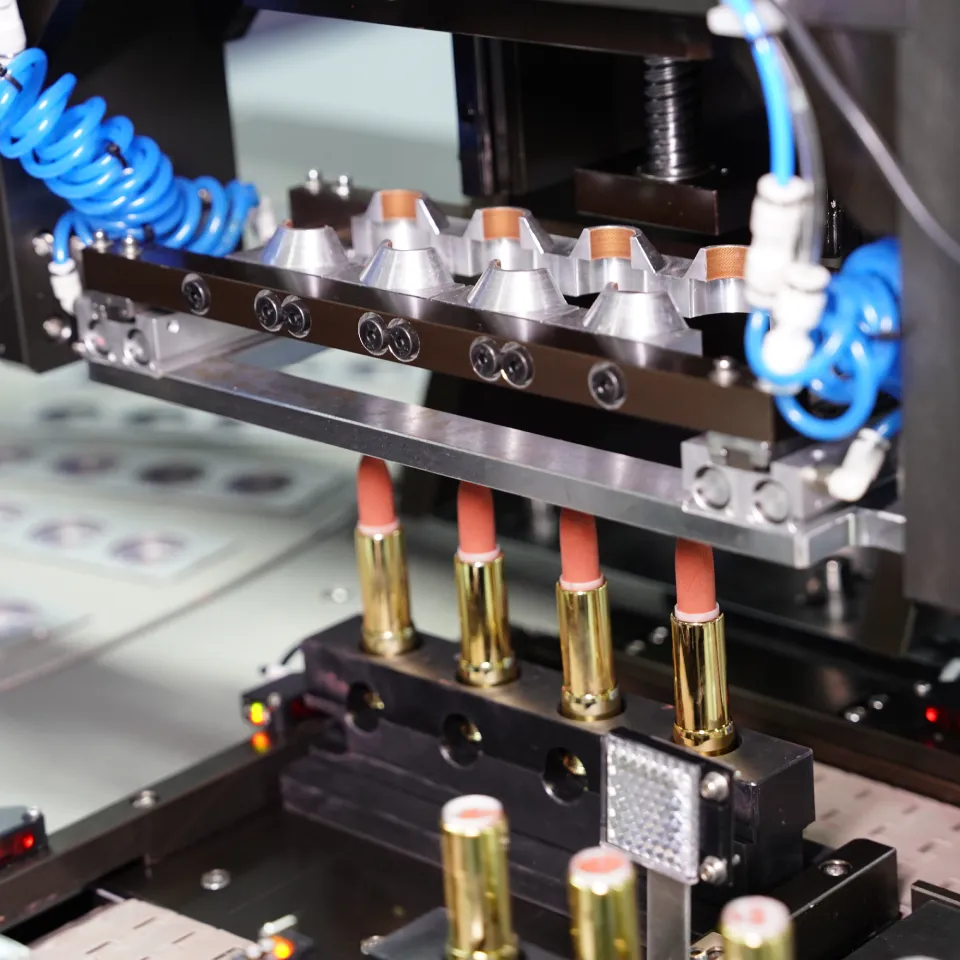

Automation and Robotic Systems

Automation in cosmetic manufacture streamlines repetitive tasks such as mixing, filling, and packaging. Robotic systems reduce human error, improve hygiene, and maintain uniform product quality.

Automated monitoring also tracks temperature, mixing speed, and ingredient ratios, ensuring each batch meets exact specifications without manual intervention.

Nanotechnology and Advanced Formulations

Nanotechnology allows cosmetic manufacturers to create smaller, more uniform particles for creams, serums, and powders. This enhances texture, absorption, and visual effects without changing formulation volume.

Advanced formulations using nanotechnology can deliver active ingredients more effectively and improve stability, offering new possibilities for product innovation and performance.

Sustainable and Eco-Friendly Manufacturing Practices

Sustainable cosmetic manufacture focuses on reducing environmental impact through energy-efficient equipment, recyclable packaging, and responsibly sourced ingredients.

Eco-friendly practices also include minimizing waste, reducing water usage, and selecting biodegradable or low-impact materials, all while maintaining product quality and safety.

Packaging and Labeling Considerations

Packaging is a critical step in cosmetic manufacture, protecting products from contamination, light, and temperature changes. It also influences consumer perception and usability.

Labels communicate essential information, including ingredients, usage instructions, and safety warnings. Both packaging and labeling must meet functional, aesthetic, and regulatory requirements.

>> Are Makeup Preservatives Safe? What You Need to Know

Protecting Product Integrity

During cosmetic manufacture, packaging is designed to maintain product stability and prevent spoilage. Airtight containers, UV-blocking materials, and tamper-evident seals are commonly used.

Proper packaging ensures creams, powders, and liquids retain texture, color, and performance until they reach the consumer.

Functional and Aesthetic Design Choices

Packaging in cosmetic manufacture balances usability and visual appeal. Pumps, droppers, and jars are selected based on product type, while design elements attract consumers.

Functionality includes ease of application, secure closures, and portability. Aesthetic considerations include shape, color, and branding that reinforce product identity.

Meeting Regulatory Labeling Requirements

Labels must accurately list ingredients, usage instructions, and any warnings according to local regulations. Cosmetic manufacturers maintain compliance to avoid legal issues and ensure consumer safety.

This includes batch numbers, expiration dates, and claims verification. Proper labeling is essential for transparency and trust in cosmetic manufacture.

Supply Chain and Distribution

Cosmetic manufacture extends beyond production to include supply chain management, ensuring products reach consumers safely and efficiently. Every step from factory to retail is carefully coordinated.

Effective distribution maintains product quality, prevents contamination, and supports timely delivery, combining logistics planning with regulatory compliance.

From Factory to Retail

Once products are manufactured and packaged, they enter the distribution network. Cosmetic manufacturers coordinate with warehouses, wholesalers, and retailers to manage inventory and delivery schedules.

Proper handling during transit is critical to preserve texture, color, and efficacy, ensuring creams, powders, and liquids arrive in optimal condition for consumers.

Logistics and Storage Requirements

Cosmetics often require controlled storage conditions, including temperature, humidity, and light protection. Warehouses use monitoring systems to maintain ideal environments.

Storage practices in cosmetic manufacture prevent spoilage, microbial growth, or ingredient degradation. Products are organized to allow easy access while minimizing risk of damage.

Tracking and Quality During Transportation

Cosmetic manufacturers implement tracking systems to monitor shipments in real-time. This ensures products are delivered on time and any issues are quickly addressed.

Quality checks may occur at multiple points during transit, verifying that containers remain sealed and product integrity is preserved throughout distribution.

Common Challenges in Cosmetic Manufacturing

Cosmetic manufacture faces unique challenges that require careful planning and scientific expertise. Scaling production, maintaining stability, and meeting safety standards are constant considerations.

Scaling from Lab to Production

Transitioning a formula from the lab to full-scale production is complex. Ingredients may behave differently in larger batches, affecting texture, color, or performance.

Cosmetic manufacturers must adjust mixing, heating, and cooling processes while maintaining ingredient ratios. Pilot batches help identify potential issues before mass production.

Maintaining Product Stability Over Time

Cosmetic manufacture must account for long-term stability. Creams, powders, and liquids can separate, discolor, or lose efficacy if not properly formulated and stored.

Stability testing evaluates temperature, humidity, light exposure, and packaging interactions. Ensuring stability over a product’s shelf life is essential for safety and consumer satisfaction.

Managing Consumer Expectations and Safety

Consumers expect cosmetics to be effective, safe, and visually appealing. Cosmetic manufacture must balance performance with regulatory and safety standards.

Manufacturers perform extensive testing to prevent allergic reactions, microbial contamination, or product failure. Meeting expectations while ensuring safety is a central challenge in the industry.

Future Trends in Cosmetic Manufacturing

Cosmetic manufacture is evolving with technology and consumer demands. Personalization, sustainability, and advanced chemistry are shaping the next generation of beauty products.

These trends focus on creating efficient, eco-friendly, and tailored products while maintaining safety, quality, and regulatory compliance.

Personalization and On-Demand Production

Future cosmetic manufacture emphasizes personalized products, where formulas can be customized for individual skin types, tones, or preferences.

On-demand production uses advanced automation and digital formulation tools to produce small batches efficiently. This approach reduces waste and caters to specific consumer needs without compromising quality.

Green Chemistry and Sustainable Sourcing

Sustainable cosmetic manufacture increasingly relies on green chemistry principles, using renewable, biodegradable, and low-impact ingredients.

Eco-friendly sourcing, energy-efficient production, and recyclable packaging reduce environmental impact while maintaining product safety and performance. This trend is becoming a standard expectation in modern cosmetic manufacturing.

Conclusion

Cosmetic manufacture combines science, creativity, and precision. From selecting ingredients to formulation, testing, and packaging, every step ensures safe, stable, and appealing products. Innovation and sustainability continue to shape the future of beauty production.

>> How Do I Start a Private Label Product? A Step-by-Step Guide

Frequently asked questions

How long does the cosmetic manufacturing process typically take?

The timeline varies by product complexity, from a few weeks for simple formulations to several months for advanced cosmetics, including R&D, testing, production, and packaging.

What role do preservatives play in cosmetic manufacturing?

Preservatives prevent microbial growth in creams, liquids, and powders, ensuring product safety and extending shelf life. Their selection balances effectiveness with consumer safety.

How is batch consistency maintained in cosmetic manufacture?

Manufacturers monitor ingredient ratios, mixing speeds, temperatures, and production conditions. Quality control checks and pilot batches ensure each product matches its intended formula.

Are natural ingredients more challenging to work with than synthetic ones?

Yes, natural ingredients can vary in potency, stability, and appearance. Cosmetic manufacture often blends natural and synthetic components to ensure reliable performance and texture.

What measures are taken to ensure cosmetics are safe for sensitive skin?

Safety testing includes irritation, allergy, and stability assessments. Formulations may exclude common allergens, fragrances, or harsh chemicals, ensuring products are gentle and safe.